How to Choose the Best PCB Maker for Your Electronics Projects

In today's rapidly evolving electronics landscape, the quality of printed circuit boards (PCBs) plays a crucial role in the overall performance and reliability of electronic devices. With the global PCB market projected to reach $78.54 billion by 2025, the demand for skilled PCB makers is higher than ever. As various industries, from telecommunications to consumer electronics, depend heavily on intricate PCB designs, selecting the right PCB maker becomes an essential consideration for engineers and hobbyists alike.

When choosing a PCB maker for your electronics projects, it is vital to assess specific criteria such as manufacturing capabilities, turnaround time, and quality certifications. A comprehensive industry report indicates that 65% of project delays arise from inadequate PCB manufacturing processes, underscoring the necessity for meticulous evaluation. Furthermore, incorporating advanced technologies such as surface mount technology (SMT) and automation can significantly enhance production efficiency, making it imperative to partner with a PCB maker that embraces innovation.

By understanding the subtleties of PCB manufacturing and the importance of choosing a reputable PCB maker, project developers can ensure that their designs translate into functional and sustainable electronic products. This introduction sets the stage for exploring the best practices and considerations for selecting the ideal PCB maker for your unique electronic endeavors.

Understanding PCB Manufacturing Processes and Technologies

PCB (Printed Circuit Board) manufacturing is a complex process that encompasses a variety of technologies and methods. Understanding these processes is crucial when selecting the best PCB maker for your electronics projects. The manufacturing process typically starts with design files generated using CAD software, which are then translated into a physical circuit board through processes such as etching, drilling, and lamination. According to IPC (Institute of Printed Circuits), the global PCB market is projected to reach $81 billion by 2025, indicating rapid growth and innovation within the industry.

Key technologies in PCB manufacturing include multilayer fabrication, surface mount technology (SMT), and flexible circuit boards. Multilayer PCBs allow for more complex circuit designs that can accommodate a higher density of components, while SMT enables the assembly of smaller components on the board, significantly increasing production efficiency. A report by Research and Markets highlights that SMT is expected to dominate the PCB assembly market, projected to grow at a CAGR of 10% through 2027. Additionally, advances in materials science have led to the development of high-frequency and high-density interconnects, further enhancing the capabilities of modern PCBs and meeting the demands of high-performance applications.

When choosing a PCB maker, consider their expertise in these manufacturing processes and the technologies they utilize. Companies that leverage advanced techniques and stay updated with industry trends can provide better quality products, shorter lead times, and more efficient production runs. As the electronics industry continues to evolve, a thorough understanding of PCB manufacturing processes will empower you to make informed decisions that align with the technical demands of your projects.

Evaluating the Quality Standards of PCB Manufacturers

When selecting a PCB manufacturer, evaluating their quality standards is crucial to ensuring the success of your electronics projects. Quality control processes and certifications play a significant role in determining the reliability and durability of the PCBs produced. Manufacturers should adhere to recognized industry standards such as IPC-A-600 for acceptability of printed boards and IPC-610 for the acceptability of electronic assemblies. This adherence reflects a commitment to maintaining high production quality, reducing defects, and enhancing overall performance.

Another important aspect to consider is the manufacturer's testing and inspection protocols. A robust quality assurance framework should include various testing methodologies, such as visual inspection, electrical testing, and functional testing, to identify any defects early in the production process. Further, evaluating the manufacturer's experience with specific technologies, such as multilayer PCBs or high-frequency applications, can also provide insight into their capability to produce the required boards to your specifications. By focusing on these quality standards, you can make a more informed decision when choosing a PCB maker, ultimately leading to a more reliable and successful electronics project.

PCB Manufacturers Quality Standards Evaluation

This bar chart illustrates the evaluation of various quality standards among different PCB manufacturers, focusing on key criteria such as Material Quality, Production Processes, Testing Standards, and Customer Support. These dimensions are crucial in choosing the best PCB maker for electronics projects.

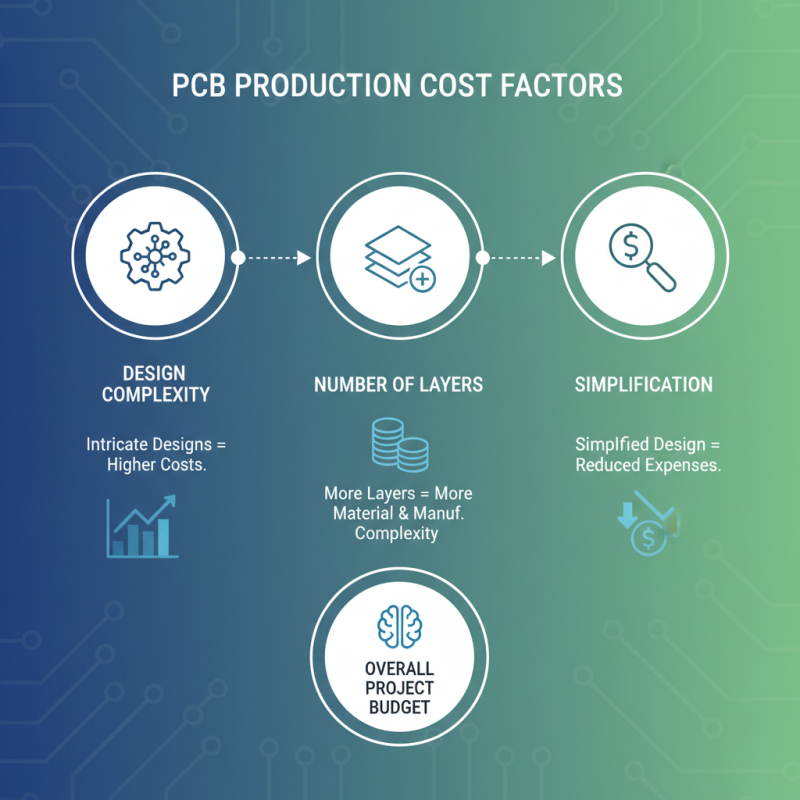

Assessing Cost Factors in PCB Production

When assessing cost factors in PCB production, it is essential to evaluate several key aspects that can affect the overall budget of your electronics project. First and foremost, the complexity of the PCB design plays a significant role in cost determination. More intricate designs typically require advanced manufacturing techniques, leading to higher production costs. Thus, simplifying the design where possible can help reduce expenses without sacrificing functionality. Additionally, the number of layers in the PCB is another critical factor; multilayer boards are more expensive due to the increased material use and manufacturing complexity compared to single-layer boards.

Another important cost consideration is the choice of materials used during PCB fabrication. Standard materials may be more cost-effective, but it's crucial to balance cost with performance requirements and the intended application of the circuit. For instance, high-frequency circuits may necessitate specialized materials that can withstand certain environmental conditions, which often leads to higher costs. Finally, the volume of PCBs ordered can significantly influence the cost-per-unit. Larger orders usually benefit from economies of scale, making it vital to assess your project's volume needs carefully. By examining these factors, you can make informed decisions that align with your budget while ensuring the PCB meets your project's specifications.

Comparing Turnaround Times and Delivery Options

When selecting a PCB maker for your electronics projects, one of the key factors to consider is the turnaround time and delivery options offered by different manufacturers. According to a 2022 report from PCB Research Institute, the average lead time for PCB production can range from 5 to 14 days, depending on the complexity of the design and the materials used. This underscores the importance of understanding not only the production capabilities of a potential PCB supplier but also their efficiency in meeting deadlines.

In the rapidly evolving electronics market, timely delivery can significantly influence project success. A survey conducted by Electronics Supply Chain Association indicated that 68% of companies experienced delays due to longer than expected PCB turnaround times. Choosing a manufacturer that offers expedited services can be invaluable, especially for businesses working on tight project timelines. Additionally, evaluating delivery options such as local vs. international shipping can further impact your ability to meet deliverables; local manufacturers often provide quicker shipping solutions, while overseas options may be cost-effective but risk longer transit times. Therefore, striking a balance between speed and cost is crucial in selecting the right PCB maker for your needs.

Researching Customer Reviews and Manufacturer Reputation

When selecting the best PCB (Printed Circuit Board) maker for your electronics projects, researching customer reviews and the manufacturer's reputation is crucial. A recent industry report indicates that about 60% of customers prioritize peer feedback before making a purchase decision, highlighting the importance of understanding what others have experienced with a PCB manufacturer. You should seek out platforms that aggregate reviews, like industry-specific forums or dedicated review sites. Pay attention to patterns in feedback – consistent complaints about quality or service may signal deeper issues with a manufacturer.

Tips: Look for reviews that mention turnaround times, communication quality, and post-sales support. A manufacturer recognized for excellent customer service will often provide a smoother project experience, reducing potential delays.

Manufacturer reputation extends beyond just customer reviews; it also encompasses certifications and industry standing. For example, a manufacturer with ISO 9001 certification demonstrates a commitment to quality management principles. According to market analysis reports, PCB firms that uphold recognized industry standards tend to experience about a 20% lower defect rate compared to those that don’t. Investigating a manufacturer's affiliations and standing in the industry can provide insight into their reliability and product quality.

Tips: Verify any certifications mentioned in reviews or on the manufacturer’s website, as these can serve as an indicator of their operational standards and commitment to quality assurance.

Related Posts

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects

-

Top 10 Printed Circuit Board Manufacturers You Should Know About

-

How to Get Quick Turn PCB Prototyping for Your Project Needs

-

Top 10 PCB Manufacturing Companies in USA for High Quality Production