Why Choose PCB Prototype Service for Your Next Project?

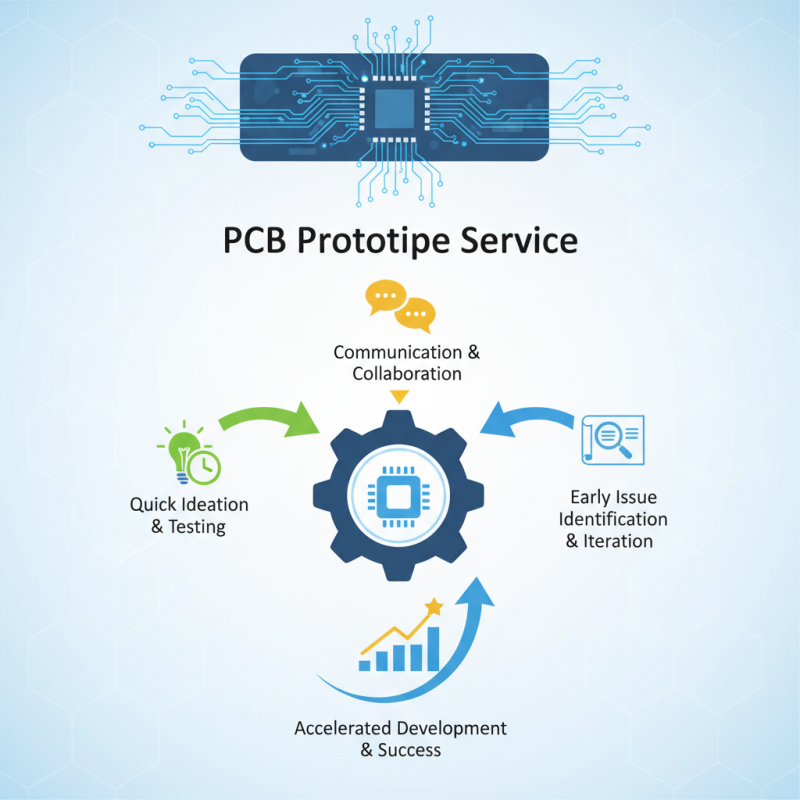

In the world of electronics, the importance of a reliable PCB prototype service cannot be overstated. As noted by Dr. Emily Wong, a leading expert in electronic design, “Quickly testing ideas is key to innovation.” This sentiment resonates with many engineers today. They understand that a quality prototype accelerates development.

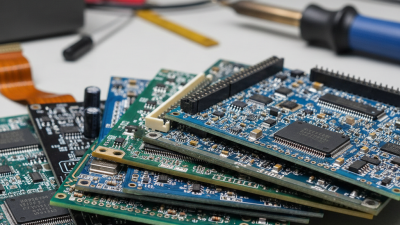

A PCB prototype service enables teams to bring their concepts to life. Rapid iterations help identify issues early in the design process. However, not all services are created equal. It's crucial to choose a provider that aligns with your project's specific needs. Many rush the process, leading to flaws that can cost time and resources.

Deeper insights reveal that communication plays a vital role in these projects. Collaborating closely with the prototype service can foster better design outcomes. Yet, some teams overlook this step, which can lead to misunderstandings. Ultimately, a strategic partnership with a trusted PCB prototype service lays the groundwork for success. Reflection on past projects can guide future decisions and enhance overall quality.

Understanding PCB Prototyping and Its Importance in Electronics Design

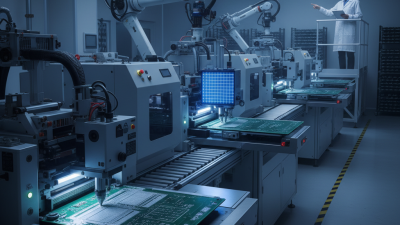

PCB prototyping is crucial in the electronics design process. It allows engineers to test their concepts before mass production. According to a recent report by IPC, 65% of companies that use prototyping see a reduction in development time. This efficiency is vital in the fast-paced tech industry.

The prototyping phase helps identify potential challenges early. For instance, circuit layout issues or material limitations can be detected and addressed. A study from Allied Market Research indicates that 70% of projects face delays due to unforeseen design flaws. Addressing these issues early can save both time and resources.

Despite its advantages, some project managers overlook prototyping. They may rush to production based on assumptions. This can lead to significant costs. A survey from Design News highlighted that nearly 40% of prototypes fail due to poor initial designs. Taking the time to prototype can prevent these costly mistakes, ensuring a smoother path to successful product launch.

Why Choose PCB Prototype Service for Your Next Project?

| Feature | Description | Benefits |

|---|---|---|

| Rapid Prototyping | Processes that allow for quick turnaround of PCB designs. | Speeds up the design iteration process, leading to faster product time-to-market. |

| Cost-Effective | Lower initial investment compared to full-scale production runs. | Ideal for startups and small projects with budget constraints. |

| Design Flexibility | Ability to experiment with different designs and layouts. | Facilitates innovation and testing of new concepts before mass production. |

| Quality Assurance | Prototypes allow for testing of performance and reliability. | Ensures the final product meets specifications and quality standards. |

| Iteration and Feedback | Prototypes enable user testing and feedback collection. | Enhances the final product through real-world input and adjustments. |

Key Advantages of Utilizing PCB Prototype Services for Projects

In today's fast-paced tech landscape, using PCB prototype services is becoming essential. These services allow engineers to transform ideas into real products quickly. The prototyping process helps identify design flaws early. This saves both time and resources in the long run.

One significant advantage is the ability to test functionality. Creating a prototype enables teams to evaluate performance before mass production. However, it can sometimes lead to unexpected results. Problems in layout or component selection might arise. These challenges prompt engineers to rethink designs and improve overall quality.

Moreover, the iterative process encourages innovation. Teams can experiment with different materials or configurations. This flexibility often leads to unique solutions. While it’s a chance for creativity, it can also create confusion. Balancing exploration and practicality is key. Embracing the imperfections in prototypes often leads to the most valuable insights for future projects.

Factors to Consider When Choosing a PCB Prototype Service Provider

When selecting a PCB prototype service provider, several factors play a crucial role.

Quality of materials is vital. Reports indicate that about 30% of prototypes fail due to subpar components.

Consider providers that use high-grade materials. This can significantly enhance your project's reliability.

Turnaround time is another key aspect. Industry data shows that 70% of projects are delayed due to slow prototyping.

Fast services may seem appealing, but ensure they maintain quality control. Balancing speed and quality is challenging but necessary.

Don't overlook customer support. About 45% of engineers report issues in communication with their PCB providers.

A provider's responsiveness can save you time and frustration during crucial phases. Look for reviews highlighting communication effectiveness.

Poor support can hinder your project's progress, leading to costly mistakes.

Common Applications and Industries Benefiting from PCB Prototypes

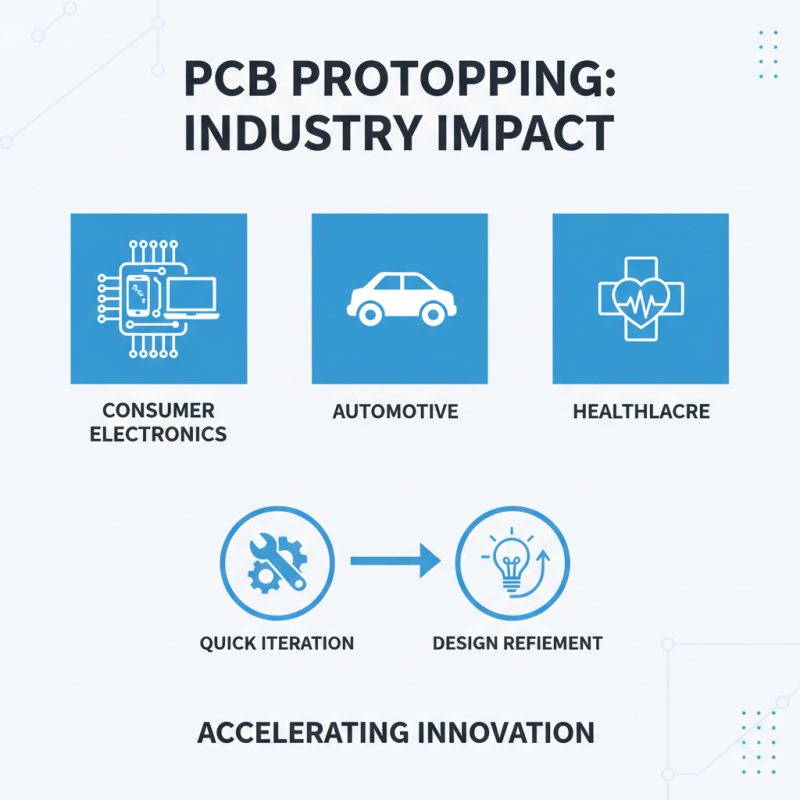

In today's fast-paced technology landscape, various industries benefit from PCB prototype services. These prototypes fit perfectly into sectors like consumer electronics, automotive, and healthcare. Companies often need to test new designs before going into full production. This is where PCB prototypes shine. They allow engineers to iterate and refine their designs quickly.

For instance, in the automotive sector, prototypes are crucial for developing new controls or sensor integrations. The swift feedback from prototypes helps in avoiding costly mistakes later on. In healthcare, prototype testing can lead to innovative devices that save lives. Rapid iterations allow for adjustments that align with strict medical standards. However, not all prototypes perform as expected. Some designs may face manufacturing challenges that require rethinking.

Consumer electronics is another field where prototypes hold great value. New gadgets often face tight launch timelines. Here, quick PCB prototypes can mean the difference between success and failure in the market. Yet, teams must also balance innovation with feasibility—sometimes ideas are too ambitious. Reflecting on the outcomes from prototypes can lead to valuable insights, enhancing future projects.

Best Practices for Collaborating with PCB Prototype Service Providers

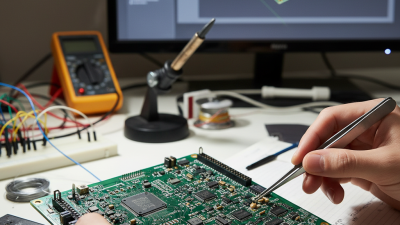

Collaborating with PCB prototype service providers can be a game-changing experience. Clear communication is essential. Be direct about your needs and expectations. Sharing detailed designs and specifications helps avoid misunderstandings. Visual aids, like sketches or diagrams, can bridge gaps in communication. Sometimes, what seems clear to you may not be apparent to them.

Feedback loops are crucial during the prototyping phase. Set regular check-in points. This allows you to assess progress and make adjustments. It’s not uncommon for initial designs to need tweaks. Be open to suggestions from the provider. They have expertise you might overlook. However, remember that too many changes can complicate the process.

Budgeting for unexpected costs is wise. Prototype services can reveal hidden design flaws, leading to changes. These changes might result in additional charges. Maintaining a flexible mindset will help you adapt. Navigation through the prototyping process isn't always smooth. However, being proactive about collaboration can lead to a successful project outcome.

Related Posts

-

How to Create a PCB Prototype for Your Electronics Project?

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects

-

How to Choose the Right PCB Fabrication Process for Your Project Needs

-

Top 10 Printed Circuit Board Manufacturers You Should Know About

-

10 Best Tips for Effective PCB Printing Techniques and Processes