Top 10 Best PCB Board Types for Efficient Circuit Design in 2023

In the ever-evolving world of electronics, the efficiency of circuit design significantly hinges on the selection of the right PCB board type. With advancements in technology, designers are increasingly prioritizing boards that can enhance performance while ensuring reliability. According to Dr. Emily Carter, a renowned expert in the PCB industry, "Choosing the appropriate PCB board is crucial for achieving optimal circuit performance and durability." Her insights underscore the importance of thoughtful selection amid the plethora of available options.

As we dive into the top 10 best PCB board types for 2023, it is essential to recognize that each type offers unique advantages tailored to specific applications. From flexible PCBs that adapt to the needs of compact devices to high-frequency boards designed for telecommunications, understanding the characteristics of each board can lead to more efficient circuit designs. This exploration aims to guide engineers and designers in making informed decisions about PCB boards, thereby fostering innovation and enhancing product capabilities.

Ultimately, the right choice in PCB board not only influences the immediate results of a circuit design project but also paves the way for future advancements within the rapidly growing electronics sector. Embracing this knowledge will enable professionals to navigate the complexities of circuit design with confidence.

Top PCB Board Types for Optimized Signal Integrity in Circuit Design

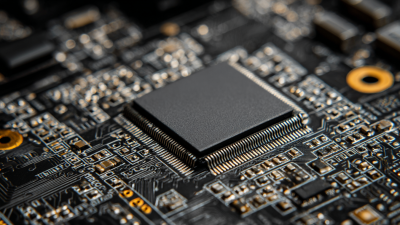

In circuit design, signal integrity is paramount for achieving optimal performance and reliability. A crucial aspect that affects signal integrity is the type of PCB board selected for a given application. The choice of board material, layer stack-up, and manufacturing processes can significantly impact how signals propagate through a circuit. For instance, high-frequency applications often benefit from low-loss materials such as PTFE or specialized composites that minimize dielectric losses, ensuring clearer signal transmission.

Moreover, the layout and configuration of the PCB play a vital role in maintaining signal integrity. Multi-layer boards can provide better isolation and ground planes, reducing electromagnetic interference and crosstalk between traces. Techniques such as controlled impedance routing and proper via design further enhance the performance of the circuit. In addition, the use of features like differential pairs can improve noise immunity, ensuring that the signals remain robust even in electrically noisy environments. By carefully selecting the PCB board type and employing best practices in design and layout, engineers can create efficient circuits that meet the demands of sophisticated electronic systems.

Advantages of Using Multilayer PCBs in High-Density Applications

Multilayer printed circuit boards (PCBs) are becoming increasingly prevalent in high-density applications due to their numerous advantages, particularly in the realm of compact electronic devices. These PCBs, which can have four or more layers, allow designers to create more complex and efficient circuits while significantly reducing the overall footprint. A report from the IPC (Institute for Printed Circuits) indicates that multilayer PCBs can facilitate a reduction in size by up to 60%, compared to traditional single or double-layer boards. This aspect is critical in today's technology landscape, where miniaturization remains a priority.

Another significant benefit of multilayer PCBs is their enhanced electrical performance. By incorporating multiple layers, designers can better manage crosstalk and signal integrity, key factors in high-speed applications. According to a study by TechInsights, multilayer PCBs can support higher frequencies, with some designs handling signals up to 10 GHz and beyond. This capability is vital in sectors like telecommunications and high-performance computing, where efficiency and reliability are paramount. Furthermore, multilayer designs also offer improved thermal management, allowing heat to dissipate more effectively through multiple planes, ensuring that devices operate within safe temperature ranges.

Comparative Analysis of Rigid vs. Flexible PCBs in 2023

When it comes to circuit design, choosing the right type of Printed Circuit Board (PCB) is crucial for achieving optimal performance. In 2023, two popular options are rigid PCBs and flexible PCBs, each with its distinct advantages and applications.  Rigid PCBs are made from solid substrates, providing stability and support for electronic components. They are ideal for products that require high precision and reliability, such as consumer electronics and automotive applications. On the other hand, flexible PCBs offer versatility and lightweight characteristics, making them suitable for compact devices where space is a constraint, such as wearable technology and medical devices.

Rigid PCBs are made from solid substrates, providing stability and support for electronic components. They are ideal for products that require high precision and reliability, such as consumer electronics and automotive applications. On the other hand, flexible PCBs offer versatility and lightweight characteristics, making them suitable for compact devices where space is a constraint, such as wearable technology and medical devices.

Tips: When selecting between rigid and flexible PCBs, consider the environmental conditions your circuit will face. Rigid PCBs are generally better for less mobile applications, while flexible options excel in dynamic environments. Additionally, assess the complexity of your design; complex layouts may benefit from the compactness and adaptability of flexible circuits.

Furthermore, the manufacturing processes for rigid and flexible PCBs differ, impacting lead times and cost. Rigid PCBs usually have a simpler production timeline due to established manufacturing techniques. In contrast, flexible PCB production can be more intricate and may incur higher costs due to the need for specialized materials and processes. Understanding these factors can help ensure that your circuit design is not only efficient but also meets economic and performance requirements.

Tips: Always prototype with your intended PCB type early in the design phase. This approach allows you to identify and resolve potential issues like thermal management and mechanical stresses before mass production.

Choosing the Right Material: FR-4 vs. High-Frequency Laminates

When it comes to selecting materials for printed circuit boards (PCBs) in 2023, the choice between FR-4 and high-frequency laminates can significantly impact the performance and efficiency of circuit designs. FR-4, a widely used material, is renowned for its balance of performance, cost, and availability. It is an epoxy resin glass fiber cloth, providing excellent dielectric properties and mechanical strength, which makes it suitable for a wide range of applications, from consumer electronics to industrial devices. However, FR-4 may not be ideal for high-frequency applications due to its limitations in signal integrity and loss at elevated frequencies.

On the other hand, high-frequency laminates are specifically designed for environments where signal integrity is paramount. These materials typically include PTFE (polytetrafluoroethylene) or ceramic-filled composites, which exhibit lower dielectric constants and dissipation factors compared to FR-4. This superior performance allows for faster signal transmission and reduced electromagnetic interference, making high-frequency laminates the material of choice for RF applications, microwave circuits, and advanced telecommunications. The decision to choose one material over the other largely hinges on the specific requirements of the circuit, including frequency, power handling, and environmental conditions. Understanding these factors is crucial for achieving both performance efficiency and cost-effectiveness in circuit design.

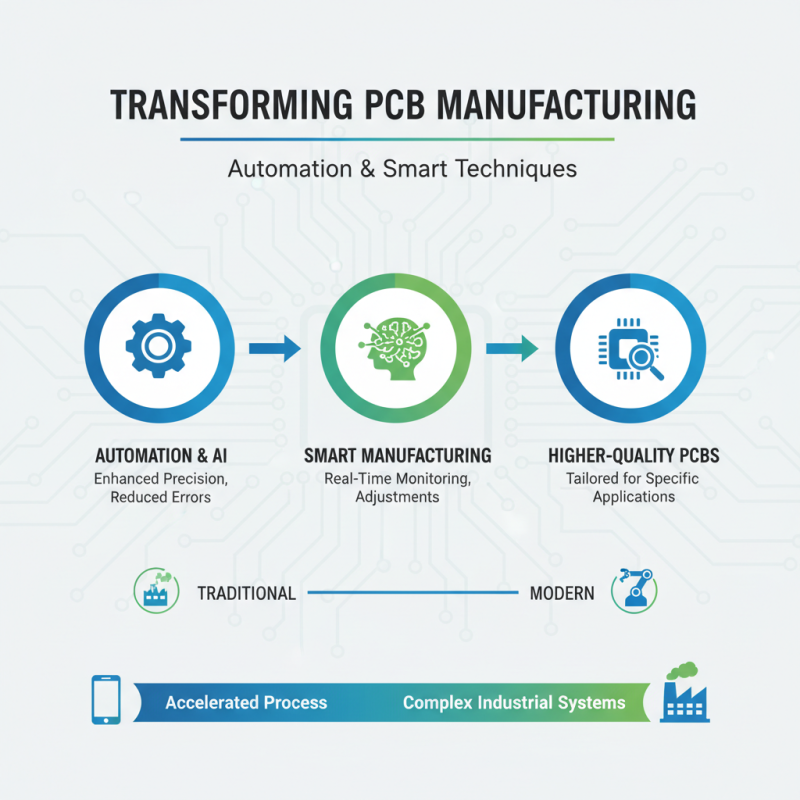

Emerging Trends in PCB Manufacturing Techniques and Their Impacts

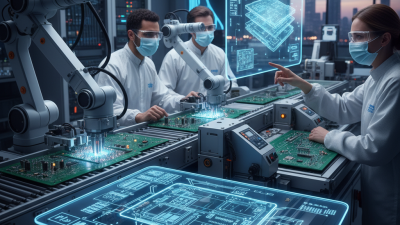

The landscape of PCB manufacturing is witnessing transformative changes driven by technological advancements and the evolving demands of modern electronics. One of the most prominent emerging trends is the integration of automation and smart manufacturing techniques. By employing AI and machine learning algorithms, manufacturers can enhance precision and reduce error rates during production. This shift not only accelerates the manufacturing process but also allows for real-time monitoring and adjustments, leading to higher-quality PCBs tailored for specific applications, from consumer electronics to complex industrial systems.

Another significant trend is the adoption of advanced materials that improve thermal management and electrical performance. With the increasing complexity of electronic devices, the need for PCBs that can withstand high temperatures and provide excellent conductivity has never been more critical. Innovations such as flexible and printed circuit boards are also gaining traction, enabling more compact designs and greater versatility in assembly. These advancements empower designers to create thinner, lighter products that meet stringent performance requirements while being environmentally friendly. As these trends continue to evolve, they will undoubtedly shape the future of circuit design and drive the next wave of innovations in the electronics industry.

Related Posts

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

Understanding the Impact of Printed Circuit Board Assembly on Today's Electronics Industry and Market Growth

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 10 Printed Circuit Board Manufacturers You Should Know

-

Top 10 PCB Assembly Services to Boost Your Electronics Production