Top PCB Board Manufacturers You Should Know About?

The landscape of electronics is constantly evolving. As technology advances, the demand for high-quality printed circuit boards (PCBs) grows. A reliable PCB board manufacturer is essential to meet these needs. They play a critical role in various industries, including automotive, medical, and consumer electronics.

Some manufacturers stand out due to their innovation and quality. Their commitment to precision ensures that components function seamlessly. However, not all manufacturers deliver the same standards. Companies must carefully evaluate potential partners. Some PCB manufacturers prioritize cost over quality, leading to long-term issues.

Choosing the right PCB board manufacturer can be challenging. It requires considering factors like expertise, technology, and reliability. A wrong decision might result in costly mistakes. Firms must remain vigilant and informed about their options in this competitive market.

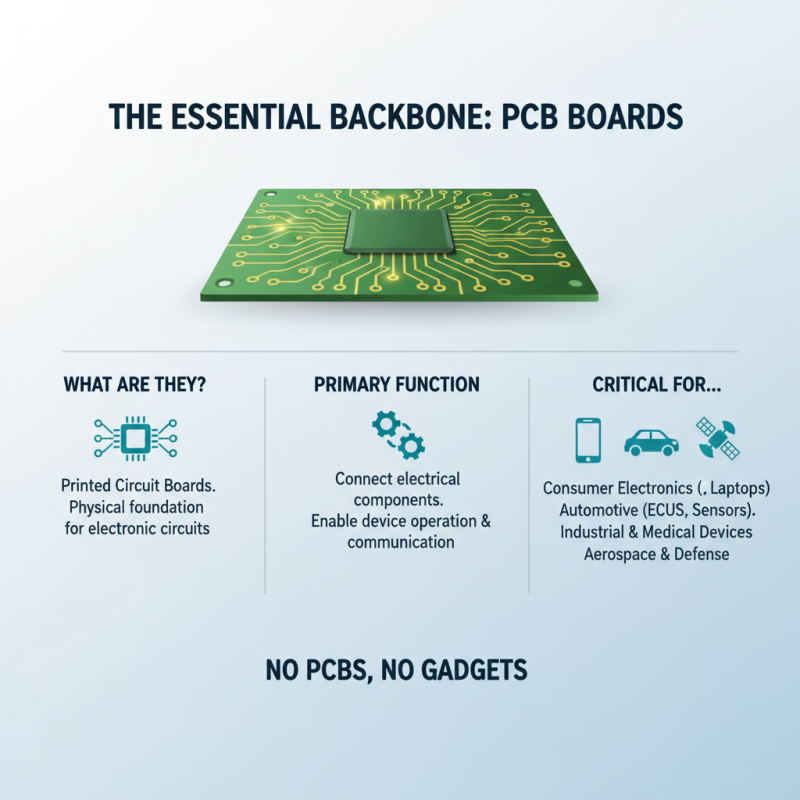

Introduction to PCB Boards and Their Importance in Electronics

PCB boards, or printed circuit boards, are fundamental to modern electronic devices. They serve as the backbone for electrical connections between components, ensuring devices operate efficiently. Their significance extends across industries, from consumer electronics to automotive. Without PCBs, our gadgets would simply not function.

When choosing a PCB, consider the design complexity. Simple designs may require basic materials. Complex boards need high-quality, durable materials. This can be confusing for newcomers. It's essential to match the material choice with the intended application.

Tip: Always assess the thermal management needs. Some boards require heat dissipation, while others don’t. This can influence your choice significantly.

Another crucial aspect is manufacturing quality. Not all PCB manufacturers maintain the same standards. Researching their processes and quality control can save time. Poor quality can lead to device failures. It is a lesson that many learn the hard way.

Tip: Inspect a manufacturer's certifications. These can provide insights into their reliability and production methods. Trustworthy sources are vital in ensuring a successful project.

Overview of the PCB Manufacturing Process and Technology

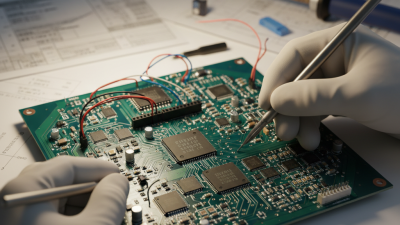

The PCB manufacturing process is intricate. It begins with design software that creates a digital layout. Engineers use advanced applications to map circuit paths and component placement. This stage is crucial, as any errors can lead to failures.

Next, raw materials form the backbone of PCB creation. Typically, fiberglass and copper are used. These materials undergo various treatments. The average thickness of common PCBs is between 0.5 mm to 3.2 mm. Techniques like laser etching help carve out finer details. However, inconsistencies in material quality can affect the final product.

After etching, layering and lamination occur. Multiple layers stack to increase functionality. Each layer must align perfectly, demanding precision. Manufacturers often face challenges in maintaining alignment, leading to costly reworks. Recent reports indicate that about 15% of PCBs may not meet quality standards upon initial inspections. This highlights a need for continuous improvement in quality control processes.

Top Global PCB Board Manufacturers: A Comparative Analysis

When exploring the landscape of PCB board manufacturers, it's crucial to understand the differences among them. Each manufacturer offers unique capabilities and technologies. Some specialize in high-frequency boards, while others focus on environmentally friendly options. It's important to research their production processes and materials used. Quality control measures can vary significantly.

Many manufacturers emphasize quick turnaround times. However, this speed can sometimes lead to compromises in quality. It's essential to consider the trade-offs involved in choosing a manufacturer based on this aspect. Additionally, some companies might have outstanding customer service but fall short in specific technical skills.

Cost is a significant factor. Lower prices might seem appealing, but they may indicate subpar materials or less rigorous testing. Companies must reflect on what aspects matter most to them. Are they prioritizing cost, time, or quality? Finding the right balance is vital for successful projects. The PCB landscape is competitive, making informed decisions crucial for achieving desired outcomes.

Top PCB Board Manufacturers You Should Know About

| Manufacturer Type | Production Capacity (units/month) | Key Technologies | Market Focus | Years in Operation |

|---|---|---|---|---|

| High-Volume Manufacturer | 500,000 | Multilayer, HDI, Mixed Technology | Consumer Electronics | 20 |

| Specialized Manufacturer | 50,000 | Flexible PCBs, Rigid-Flex | Aerospace & Defense | 15 |

| Prototype Manufacturer | 1,000 | Rapid Prototyping, Low Volume | Startups & R&D | 10 |

| Value-added Manufacturer | 200,000 | Assembly Services, Testing | Industrial Equipment | 25 |

| Eco-Friendly Manufacturer | 150,000 | Biodegradable Materials, Lead-free Solder | Green Technology | 12 |

Key Factors to Consider When Choosing a PCB Manufacturer

Choosing the right PCB manufacturer is crucial for the success of your project. Quality, reliability, and cost are key factors to consider. According to a recent report by IPC (Institute of Printed Circuits), over 80% of PCB failures stem from poor manufacturing practices. This underscores the importance of selecting a company with proven quality control processes.

When evaluating manufacturers, consider their production capabilities. Are they equipped to handle your specific PCB types? For instance, some manufacturers excel in high-frequency designs or complex multi-layer boards. Look for certifications, such as ISO 9001, to assess their commitment to quality. High-quality boards can reduce long-term costs significantly, even if upfront expenses are higher.

Tips: Always request sample PCBs before making a bulk order. This allows you to inspect the quality firsthand. Also, review their delivery timelines. Delays in production can derail your entire project. Remember, the cheapest option may not always be the best; sometimes quality comes at a premium. Be wary of companies that promise unrealistically fast turnaround times or extremely low prices, as these may indicate corners being cut.

Top PCB Board Manufacturers: Key Factors to Consider

This bar chart illustrates key factors to consider when selecting a PCB manufacturer, rated on a scale from 1 to 10 based on importance. The highest ratings are for Quality and Customer Support, indicating their critical role in the decision-making process.

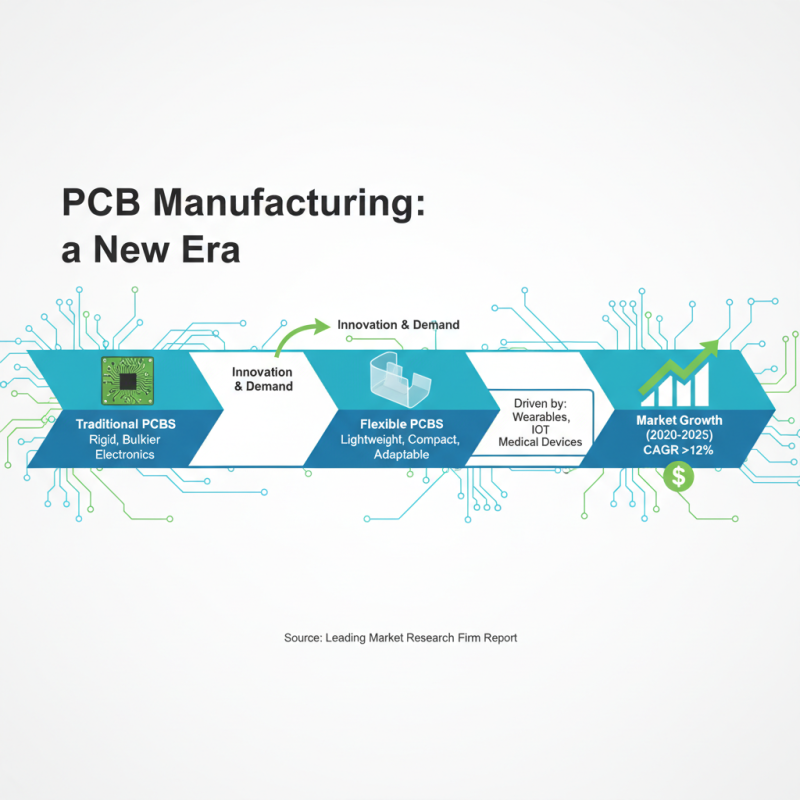

Trends and Innovations in PCB Manufacturing Industry

The PCB manufacturing industry is experiencing rapid transformation. Innovations are reshaping processes and materials. For instance, the shift towards flexible PCBs is driven by the increasing demand for lightweight and compact electronics. According to a report from a leading market research firm, the flexible PCB market is projected to grow at a compound annual growth rate (CAGR) of over 12% through 2025.

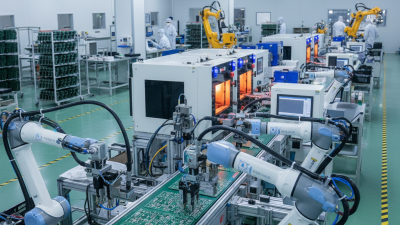

Another significant trend is the push towards automation in PCB production. Automation enhances efficiency and reduces human error. A recent study highlighted that automated systems can increase production speeds by up to 30%. However, this transition comes with challenges. Many manufacturers still rely on traditional methods, which may hinder their competitiveness. Adapting to new technologies requires investment and training, which some companies struggle to manage.

Sustainability is also becoming a priority. Environmental concerns are driving manufacturers to develop eco-friendly materials and processes. The European PCB industry aims for a 50% reduction in waste by 2030. Yet, the implementation of sustainable practices can be complex and costly. Balancing profitability with sustainability goals remains an ongoing struggle for many firms in the sector. This pursuit of innovation, efficiency, and responsibility will define the future of PCB manufacturing.

Related Posts

-

Top 10 Tips for Efficient Circuit Board Manufacturing Process Optimization

-

Top 10 PCB Manufacturing Techniques You Need to Know for High Quality Circuits

-

Discover the Top PCB Manufacturers Near Me: Your Ultimate Guide to Local Electronics Solutions

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

10 Essential Tips for Successful PCB Fabrication

-

What is a PCB Prototype and How Does it Work?