Top 10 PCB Manufacturing Companies in USA for High Quality Production

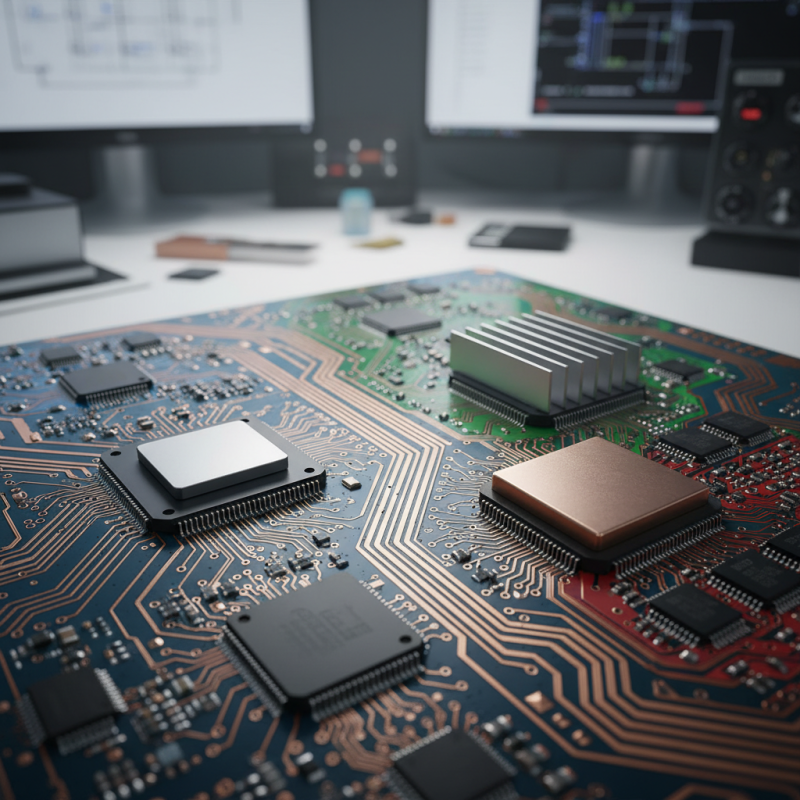

In the rapidly advancing world of electronics, the importance of high-quality printed circuit boards (PCBs) cannot be overstated. The demand for reliable and efficient PCB manufacturing has surged, particularly in the USA, where technological innovation thrives across various industries. Understanding the landscape of PCB manufacturing USA is crucial for businesses aiming to stay competitive and meet the rigorous standards of performance and reliability required by modern applications.

This article delves into the top PCB manufacturing companies in the United States, highlighting their commitment to quality production and innovative processes. By examining the leading players in this sector, we aim to provide insights into the capabilities and strengths that set these companies apart. Whether you're a startup or an established enterprise, knowing where to turn for expert PCB manufacturing services can be a game-changer in accelerating product development and enhancing overall efficiency. Join us as we explore the top contenders in the PCB manufacturing landscape, poised to deliver excellence in every circuit.

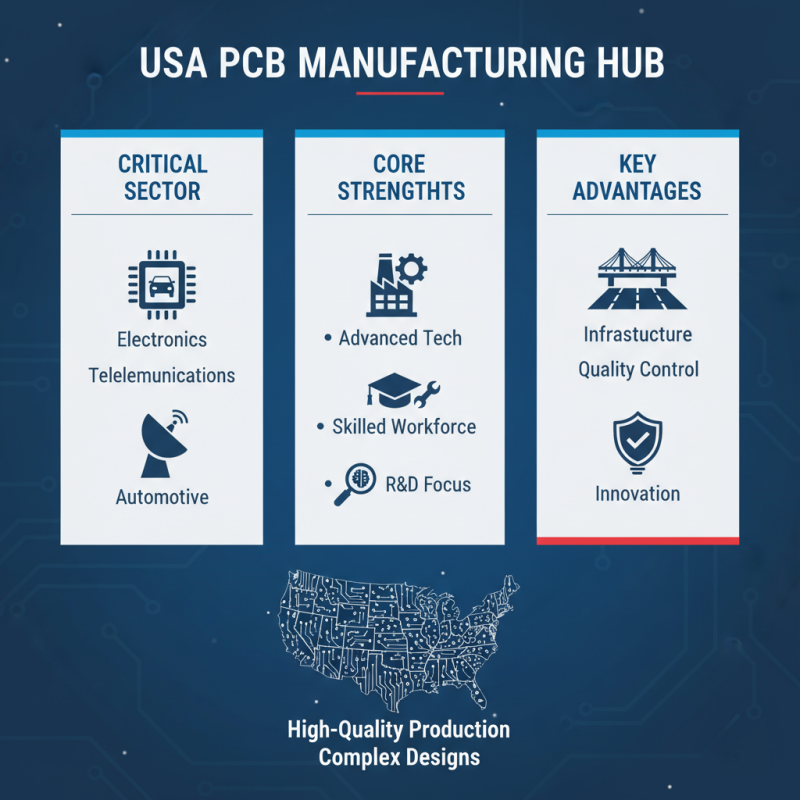

Overview of PCB Manufacturing in the USA

PCB manufacturing in the USA is a critical sector that supports a wide range of industries, including electronics, automotive, and telecommunications. The United States has established itself as a hub for high-quality printed circuit board (PCB) production, leveraging advanced technology and strict quality control measures. Key factors contributing to its prominence include a well-developed infrastructure, a skilled workforce, and a strong emphasis on research and development. This environment fosters innovation, enabling manufacturers to produce increasingly complex designs that meet the demands of modern applications.

In recent years, the PCB manufacturing landscape in the USA has seen significant advancements, particularly in the realm of automation and efficiency. Companies are investing heavily in state-of-the-art equipment and drive for sustainability to enhance production capabilities while minimizing environmental impact. As global markets evolve and the need for high-quality electronics increases, American PCB manufacturers are positioning themselves to lead in design versatility and production excellence. The combination of local expertise and advanced technology creates a competitive advantage, making the USA a preferred destination for high-quality PCB production.

Criteria for Selecting Top PCB Manufacturing Companies

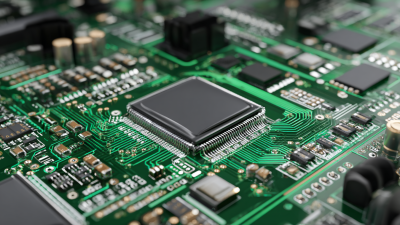

When selecting top PCB manufacturing companies in the USA, several critical criteria should guide your decision-making process. First and foremost, quality assurance plays a significant role. Companies that adhere to industry standards such as IPC-600 and IPC-A-610 ensure that the PCBs are produced with the highest level of quality. It is essential to verify if the manufacturer implements rigorous testing protocols, including electrical tests and visual inspections, to maintain product reliability.

Another important criterion is the range of services offered by the PCB manufacturer. A company that provides comprehensive solutions, from design to prototype and mass production, can significantly streamline the development process. Additionally, capability in various technologies such as rigid, flexible, and high-frequency PCBs allows for greater versatility in fulfilling diverse project requirements. It's also beneficial to consider the manufacturer's production capacity and lead times, as these factors directly impact project timelines and overall efficiency.

Top 10 PCB Manufacturing Companies in USA for High Quality Production

| Company Location | Manufacturing Capabilities | Annual Production Volume | Industry Specialization | Certifications | Lead Time |

|---|---|---|---|---|---|

| California | Flex, Rigid-Flex, HDI | 5 million units/year | Consumer Electronics, Medical | ISO 9001, IPC-A-600 | 2 weeks |

| Texas | Multilayer, High Frequency | 3 million units/year | Telecommunications, Aerospace | AS9100, IPC-6012 | 4 weeks |

| New York | Rigid, Rigid-Flex | 2 million units/year | Industrial, Medical | ISO 13485, IPC/WHMA-A-620 | 3 weeks |

| Florida | Flexible, HDI | 4.5 million units/year | Consumer Products, Automotive | ISO 9001, IPC-A-610 | 5 weeks |

| Illinois | Multilayer, Rigid | 6 million units/year | Aerospace, Defense | AS9100, IPC-6013 | 6 weeks |

| Ohio | HDI, Rigid-Flex | 3.5 million units/year | Consumer Electronics, Medical | ISO 9001, IPC-A-610 | 2.5 weeks |

| Georgia | Flex, Rigid | 1.5 million units/year | Telecommunications, Automotive | IPC-6012, ISO 9001 | 4 weeks |

| Washington | Multilayer, High Frequency | 3 million units/year | Medical, Industrial | ISO 13485, IPC-A-600 | 3 weeks |

| Colorado | Rigid, Rigid-Flex | 2 million units/year | Consumer Electronics, Aerospace | AS9100, IPC-6013 | 4 weeks |

| Massachusetts | High Density, Flexible | 5 million units/year | Telecommunications, Medical | ISO 9001, IPC-A-610 | 3 weeks |

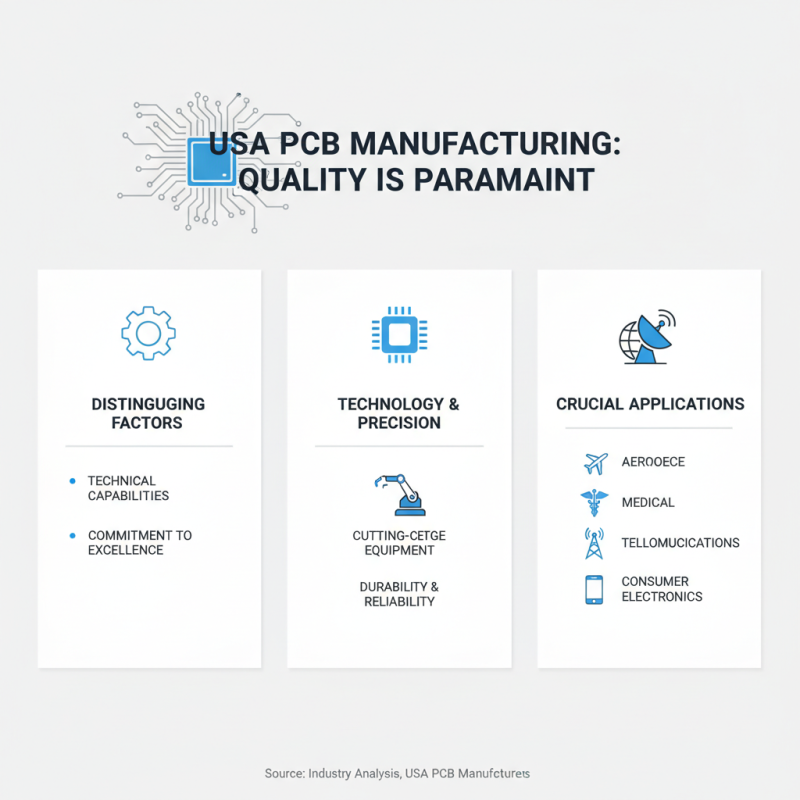

List of Top 10 PCB Manufacturing Companies in the USA

When it comes to finding reliable PCB manufacturing companies in the USA, quality is paramount. The top players in the industry are distinguished not only by their technical capabilities but also by their commitment to excellence in each stage of production. These companies typically leverage cutting-edge technology to ensure precision and durability in their PCBs, which are crucial for various applications across sectors such as aerospace, medical, telecommunications, and consumer electronics.

Moreover, the best PCB manufacturers in the USA emphasize the importance of custom solutions tailored to meet the unique specifications of their clients. From prototype development to large-scale production runs, these organizations maintain rigorous quality control processes, including advanced testing methods to guarantee product performance. They also focus on efficient turnaround times and responsive customer service, which are key factors that contribute to their reputation in the competitive landscape of PCB manufacturing.

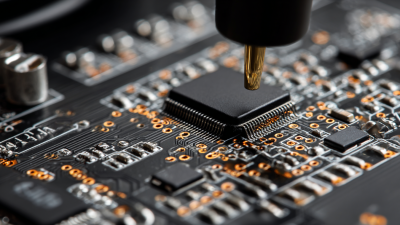

Key Technologies and Innovations in PCB Production

In the rapidly evolving landscape of electronics, the significance of advanced technologies in PCB (Printed Circuit Board) production cannot be overstated. Key innovations such as HDI (High-Density Interconnect), embedded passive components, and flexible PCBs are transforming manufacturing processes. According to industry reports from IPC, the global PCB market reached a valuation of approximately $66 billion in 2020, with projections indicating a growth rate of about 4% annually. This growth is largely driven by the increasing demand for high-frequency applications and miniaturization in consumer electronics.

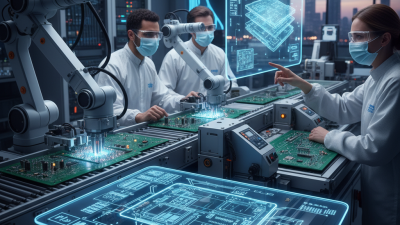

Moreover, automation and digitalization are revolutionizing PCB manufacturing workflows. The integration of AI and IoT technologies facilitates real-time monitoring and predictive maintenance, leading to enhanced efficiency and reduced operational costs. A report from Technavio highlights that adopting Industry 4.0 practices can reduce manufacturing downtime by up to 25%. Furthermore, advancements in manufacturing techniques, such as robotic assembly and laser direct imaging, are enabling companies to achieve tighter tolerances and higher reliability in their products, essential for meeting the stringent demands of aerospace, automotive, and medical industries. High-quality PCB production is becoming indispensable in ensuring the performance and longevity of electronic devices in an increasingly connected world.

Future Trends in PCB Manufacturing Industry in the USA

The PCB manufacturing industry in the USA is poised for significant advancements driven by technological innovations and market demands. One of the prominent trends shaping the future is the increasing integration of automation and artificial intelligence (AI) in PCB production processes. According to a report from Research and Markets, the global PCB market is expected to grow at a compound annual growth rate (CAGR) of 4.5% through 2025, highlighting a pivotal shift towards more efficient manufacturing practices. Automation not only improves production speed but also enhances precision, reducing the potential for errors in the intricate designs that modern electronics require.

Another emerging trend is the growing focus on sustainability within the PCB manufacturing sector. As environmental regulations tighten, companies are exploring eco-friendly materials and processes. A study by Mordor Intelligence indicates that the trend towards greener manufacturing practices is gaining traction, with an emphasis on reducing e-waste and employing recycling methods in production. Manufacturers are increasingly adopting renewable energy sources and sustainable materials to align with consumer preferences and regulatory requirements, ensuring they remain competitive in a rapidly evolving market. This commitment to sustainability not only benefits the environment but also attracts a new consumer base that values responsible production methods.

Related Posts

-

Unlocking Innovation with Top US Based PCB Manufacturers for Your Project Needs

-

Top 10 Tips for Efficient Circuit Board Manufacturing Process Optimization

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

2025 How to Optimize PCB Layout for Better Performance and Efficiency

-

Top 10 Printed Circuit Board Manufacturers You Should Know

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects