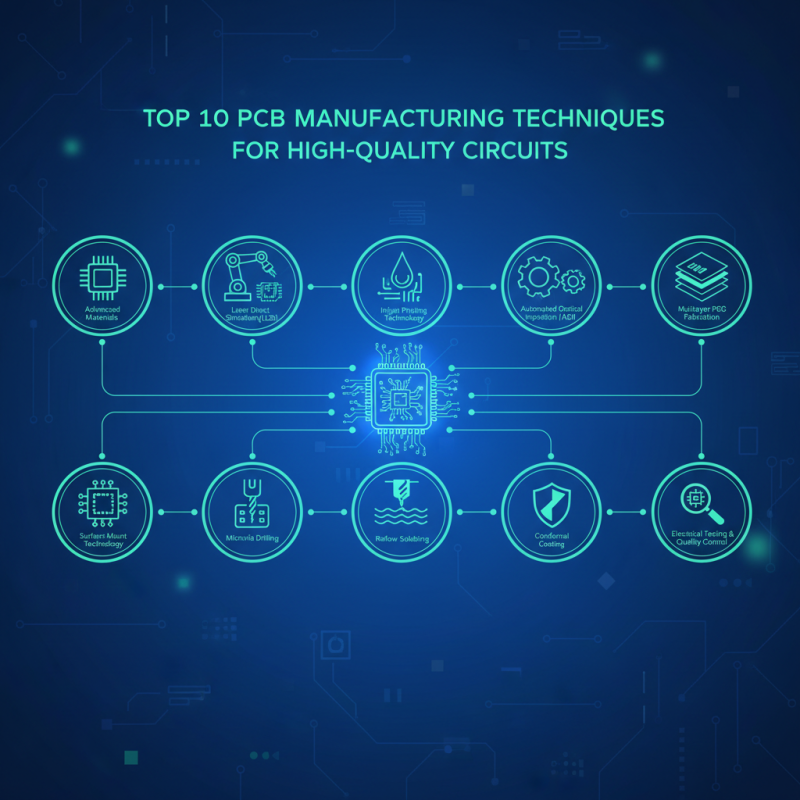

Top 10 PCB Manufacturing Techniques You Need to Know for High Quality Circuits

In the realm of electronics, the importance of high-quality circuit boards cannot be overstated. PCB manufacturing plays a crucial role in the performance, reliability, and longevity of electronic devices. As technology continues to evolve, manufacturers are constantly seeking innovative techniques to enhance the quality and efficiency of their production processes. Understanding the various PCB manufacturing techniques is essential for anyone involved in the design and production of circuits, whether in a commercial capacity or as a hobbyist.

This article delves into the top 10 PCB manufacturing techniques that are integral to achieving superior circuit quality. From advanced materials to cutting-edge fabrication methods, we will explore the best practices that can elevate the standard of PCB creation. By adopting these techniques, manufacturers can not only improve the functionality of their products but also keep pace with the increasingly competitive landscape of electronic manufacturing. Join us as we uncover the essential approaches that every PCB designer and manufacturer should be aware of to ensure their circuits meet the highest quality standards.

Overview of PCB Manufacturing Techniques for Quality Circuits

In the realm of electronics, the quality of printed circuit boards (PCBs) significantly impacts the overall performance of devices. Understanding various PCB manufacturing techniques is essential for ensuring high-quality circuits. The process starts with precise design and layout using specialized software, which is crucial for creating efficient paths for electrical signals. This design phase must include considerations for the materials used, as different substrates can affect conductivity and thermal performance.

Once the design is finalized, the manufacturing process typically involves several key techniques. These include etching, which removes unwanted copper from the board to form the circuit layout, and lamination, where multiple layers are fused together for complex circuits. Additionally, the techniques of solder mask application and surface mount technology are vital for protecting the boards and facilitating the assembly of components. Each of these methods requires meticulous attention to detail and adherence to specific standards to produce PCBs that are not only functional but also reliable in demanding applications. By mastering these techniques, manufacturers can enhance the quality and longevity of their circuits, ultimately leading to superior product performance.

Key Materials Used in High-Quality PCB Production

In the pursuit of high-quality PCB production, the selection of key materials is crucial. The base material, typically a laminate like FR-4, plays a significant role in determining the performance and durability of the circuit board.

FR-4 is a glass-reinforced epoxy laminate that not only provides excellent electrical insulation but also ensures mechanical strength. For more advanced applications, materials such as polyimide or Rogers substrates are often utilized due to their superior thermal stability and dielectric properties, making them suitable for high-frequency and high-temperature environments.

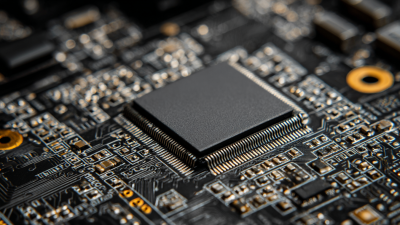

Another important component in PCB manufacturing is the copper layer, which serves as the conductive pathway for electrical signals. The thickness and quality of the copper foil can affect the board's performance, with thicker copper providing better current-carrying capacity. Additionally, solder mask and silkscreen materials are essential for protecting the copper traces and facilitating assembly. High-quality solder masks can withstand heat during soldering processes, while durable silkscreens ensure that any printed labels and graphics maintain their integrity throughout the board's lifespan. Overall, the choice of materials directly impacts the reliability and longevity of the final product.

Step-by-Step Guide to Surface Mount Technology (SMT)

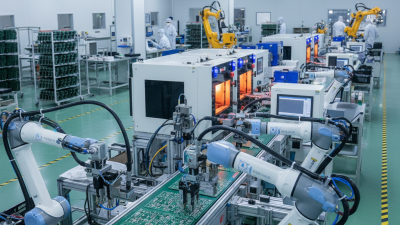

Surface Mount Technology (SMT) has revolutionized the way printed circuit boards (PCBs) are manufactured, allowing for more compact designs and improved performance. SMT involves soldering electronic components directly onto the surface of the PCB rather than through holes, leading to a more efficient production process. This technique not only accommodates a higher density of components but also simplifies automated assembly, reducing labor costs and the potential for human errors.

The step-by-step process of SMT begins with the application of solder paste onto designated areas of the PCB, which is typically accomplished using a stencil. Following this, components are placed onto the solder-covered pads in a precise manner, often utilizing pick-and-place machines. Once the components are positioned, the board undergoes reflow soldering, where heat is applied to melt the solder paste and ensure a reliable electrical connection.

This streamlined approach minimizes assembly times and significantly enhances production scalability, making SMT an indispensable method in modern electronics manufacturing.

Importance of PCB Etching in Circuit Quality Assurance

PCB etching is a critical process in ensuring high-quality circuits. This technique involves the removal of unwanted copper from the surface of a printed circuit board (PCB) to create precise circuit patterns. The quality of etching directly impacts the performance and reliability of the final product. Any inconsistencies or errors in the etching process can lead to circuit failures, making it imperative for manufacturers to adhere to best practices.

To ensure successful PCB etching, it is crucial to maintain optimal conditions throughout the process. First, the etching solution should be consistently monitored for concentration and temperature, as these factors heavily influence etching speed and accuracy. Additionally, using high-resolution photolithography for mask creation can greatly enhance the precision of the etching process, minimizing the chances of undesired copper removal.

**Tips:** Always consider the type of etching system employed—whether chemical or laser—as this determines the overall quality and speed of production. Furthermore, post-etching cleaning is essential to remove any residues that might affect circuit performance. Regularly inspecting the etching equipment and maintaining cleanliness in the workspace can also improve the efficiency and quality of PCB manufacturing.

Top 10 PCB Manufacturing Techniques for High Quality Circuits

This bar chart represents the effectiveness rating of various PCB manufacturing techniques, highlighting the importance of PCB etching in ensuring circuit quality.

Quality Control Measures in PCB Manufacturing Processes

Quality control measures are critical in PCB manufacturing to ensure high-quality circuits that meet industry standards. The demand for precision in electronic components has driven manufacturers to adopt stringent quality management processes. According to a report by Electronics Manufacturing Services (EMS) industry experts, implementing comprehensive quality control can reduce defect rates by up to 30%, which directly translates to increased customer satisfaction and reduced production costs.

One of the most effective quality control measures in PCB manufacturing is the use of automated optical inspection (AOI) systems. These systems are capable of detecting defects such as misalignments, solder issues, and component placement errors at various stages of the production process. A study published in the International Journal of Electronics notes that the integration of AOI can enhance detection rates by 90%, enabling manufacturers to identify and rectify problems before the final assembly. Additionally, regular audits and adherence to international standards like IPC-A-600 further reinforce the reliability and quality of PCBs produced.

Furthermore, continuous training and skill development for employees involved in the manufacturing process play a vital role in quality assurance. A report by the Institute of Printed Circuits found that companies that invest in employee training programs observe a 35% reduction in human error-related defects. By fostering a culture of quality awareness and skill enhancement, PCB manufacturers can significantly improve their production processes, leading to better end-products in a highly competitive market.

Top 10 PCB Manufacturing Techniques You Need to Know for High Quality Circuits - Quality Control Measures in PCB Manufacturing Processes

| Technique | Description | Quality Control Measure | Typical Application |

|---|---|---|---|

| Screen Printing | A process for applying ink to the PCB surface to create circuitry. | Regular inspection of screen quality and alignment. | High-frequency circuits, RF applications. |

| Etching | Removal of unwanted copper from the PCB substrate. | Monitoring etchent concentration and temperature. | General circuit board manufacturing. |

| Drilling | Creating holes in the PCB for vias and component leads. | Using laser measurement to ensure hole diameter accuracy. | Multilayer boards, complex circuits. |

| LAMINATION | Bonding multiple layers of the PCB material. | Thermal and pressure monitoring during the process. | High-density interconnection (HDI) PCBs. |

| Component Placement | Automated or manual placement of components onto the PCB. | Optical inspection of component placement. | All electronic devices. |

| Soldering | Melting solder to secure components to the PCB. | X-ray inspection for solder joint integrity. | Surface-mount technology (SMT) applications. |

| Testing | Verifying the function and quality of the finished PCB. | In-circuit and functional testing. | Final product validation. |

| Surface Finishing | Applying protective coatings to the PCB. | Thickness measurement of the finish. | Corrosion resistance in harsh environments. |

| Conformal Coating | Applying a protective coating to protect against moisture and dust. | Visual inspection and adhesion tests. | Environmental protection for electronics. |

| Packaging | Final packaging of the PCBs for shipping. | Verification of packaging integrity. | Shipping to clients. |

Related Posts

-

Top 10 Tips for Efficient Circuit Board Manufacturing Process Optimization

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Unlocking Efficiency: The Future of PCB Production Techniques in Modern Electronics

-

Understanding the Impact of Printed Circuit Board Assembly on Today's Electronics Industry and Market Growth

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry