Top 10 Printed Circuit Board Manufacturers You Should Know About

In the rapidly evolving landscape of electronics, printed circuit boards (PCBs) play a pivotal role in integrating various components to create functional devices. The complexities of modern technology demand precision and reliability, making the choice of printed circuit board manufacturers a critical factor for success in any electronic project. With a plethora of companies offering PCB manufacturing services, it can be challenging to identify those that truly stand out in terms of quality, innovation, and customer service.

This article aims to shed light on the top printed circuit board manufacturers you should know about, providing insights into their capabilities, expertise, and the unique value they bring to the industry. By understanding the strengths and offerings of these manufacturers, engineers, and business owners can make informed decisions that enhance the performance and reliability of their electronic products. Whether you’re looking for rapid prototyping, mass production, or specialized designs, knowing the right manufacturers can lead to fruitful partnerships and successful outcomes in your projects.

Overview of Printed Circuit Boards and Their Importance

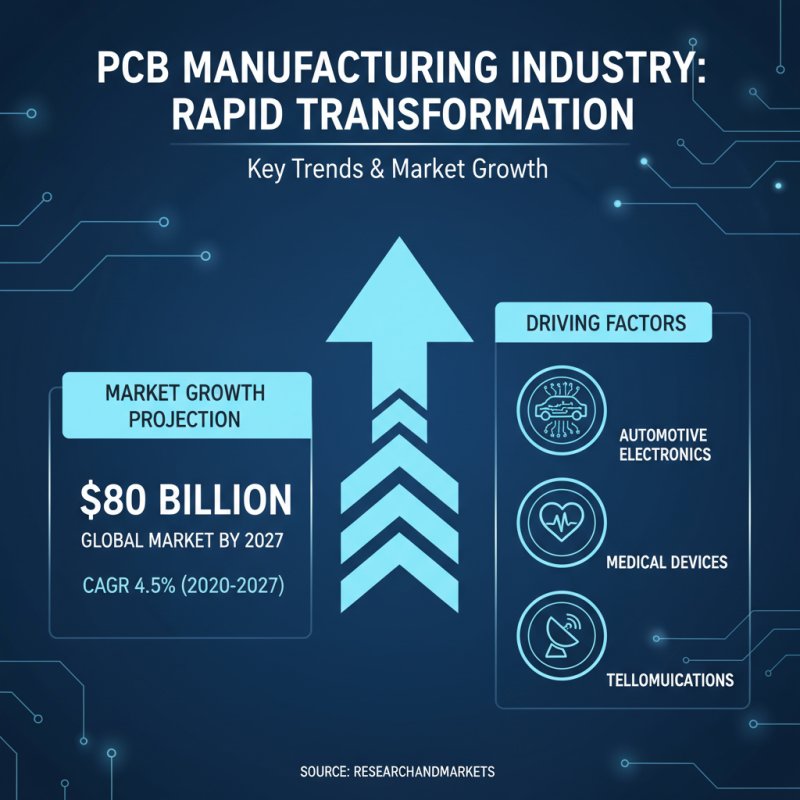

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, acting as the backbone that connects electronic components and enables communication within a circuit. According to industry reports, the global PCB market has been valued at approximately $60 billion in 2020, with projections suggesting a growth that could reach over $80 billion by 2025. This growth is largely driven by the increasing demand for electronics across various sectors such as telecommunications, automotive, and consumer electronics, where the complexity and miniaturization of devices continue to rise.

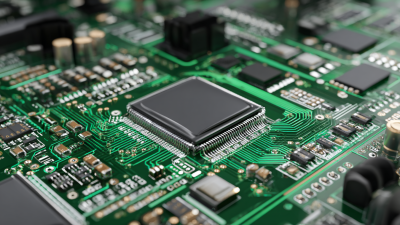

The importance of PCBs extends beyond mere structural support; they play a pivotal role in ensuring the electrical performance and reliability of electronic assemblies. Advanced technologies have made it possible to produce multi-layer and flexible PCBs, accommodating more functions in smaller spaces, which is essential for the development of next-generation products. The advent of trends like the Internet of Things (IoT) and smart technologies has further fueled the demand, highlighting the necessity for high-quality manufacturing standards. Reports indicate that about 50% of all new PCB designs now include advanced features, emphasizing the critical role that manufacturers play in enhancing the capabilities of PCBs in meeting modern electronic requirements.

Top 10 Printed Circuit Board Manufacturers by Production Volume

Criteria for Selecting Top PCB Manufacturers

When selecting the top printed circuit board (PCB) manufacturers, several key criteria must be considered to ensure quality, reliability, and overall performance. First and foremost, a manufacturer’s production capabilities are vital. According to industry reports, the global PCB market is expected to reach approximately $78 billion by 2027, driven by advancements in technology and the growing demand for electronics. A capable manufacturer should possess state-of-the-art equipment and the ability to handle a variety of PCB types, including rigid, flexible, and multilayer boards, as well as the capacity to scale production based on demand.

Another significant criterion is the manufacturer’s certifications and adherence to industry standards. Certifications such as ISO 9001, IPC-A-600, and IPC-A-610 ensure that the manufacturer complies with international quality management and inspection standards, which are critical in maintaining product reliability and minimizing defects. Furthermore, the company's past performance, indicated by customer reviews and case studies, plays an essential role in evaluating their reputation in the industry. According to a survey by IPC, nearly 75% of companies prioritize manufacturers with proven track records in timely delivery and customer service excellence. An emphasis on continuous improvement and innovation is also crucial, as the PCB landscape is ever-evolving, necessitating manufacturers to stay ahead through research and development.

Top 10 Printed Circuit Board Manufacturers You Should Know About

| Manufacturer Location | Annual Revenue (USD) | Employees | Years in Business | Certifications |

|---|---|---|---|---|

| North America | $500 Million | 1500 | 20 | ISO 9001, IPC Certified |

| Europe | $300 Million | 800 | 15 | ISO 13485, RoHS Compliant |

| Asia | $700 Million | 2500 | 30 | ISO 9001, IPC-A-600 |

| North America | $250 Million | 500 | 10 | ISO 9001, ITAR Registered |

| Asia | $400 Million | 1200 | 25 | ISO 9001, TS 16949 |

| Europe | $350 Million | 950 | 18 | ISO 14001, IPC 6012 |

| Asia | $600 Million | 2000 | 28 | ISO 9001, UL Listed |

| North America | $270 Million | 700 | 12 | ISO 9001, RoHS Compliant |

| Europe | $320 Million | 850 | 17 | ISO 9001, AEC-Q100 |

Detailed Profiles of the Leading PCB Manufacturers

When it comes to the printed circuit board (PCB) industry, understanding the key players is essential for anyone involved in electronics manufacturing. The top manufacturers have established themselves with a reputation for high quality, innovation, and reliability. Each of these companies offers a unique set of capabilities, from rapid prototyping to mass production, catering to various sectors such as consumer electronics, automotive, and telecommunications.

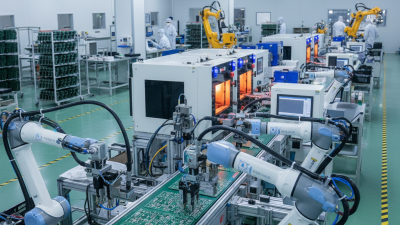

The leading PCB manufacturers employ advanced technologies and stringent quality control measures to ensure that their products meet the highest standards. Many of these companies have invested heavily in automation and state-of-the-art manufacturing techniques, which enhance production efficiency and output consistency. Additionally, they often focus on sustainability and eco-friendly practices, addressing the growing demand for environmentally responsible manufacturing processes.

Moreover, these manufacturers typically offer comprehensive services, including design support, testing, and logistics management. By positioning themselves as end-to-end solutions providers, they not only streamline the supply chain for their clients but also foster long-term partnerships. Their expertise and commitment to innovation enable them to stay ahead of the rapidly evolving electronics landscape, making them indispensable players in the global market.

Emerging Trends in PCB Manufacturing Technology

The printed circuit board (PCB) manufacturing industry is witnessing rapid transformation driven by emerging technologies and market demands. According to a recent industry report projected by ResearchAndMarkets, the global PCB market is anticipated to reach approximately $80 billion by 2027, growing at a CAGR of 4.5% from 2020. This growth is largely influenced by increased demand in sectors such as automotive electronics, medical devices, and telecommunications, where the integration of advanced functionalities is paramount.

One of the key trends in PCB manufacturing technology is the shift towards automation and smart manufacturing. The adoption of Industry 4.0 principles, which emphasize the use of IoT (Internet of Things) and AI (Artificial Intelligence), is enabling manufacturers to enhance production efficiency and reduce costs. Automation in PCB assembly processes can lead to significant improvements in production speed, with some reports indicating reductions in lead time by up to 30%. Additionally, developments in materials science are facilitating the production of lighter and more durable PCBs, with advances in flexible and rigid-flex circuit designs becoming increasingly prevalent. This material innovation supports the miniaturization of electronics—a critical factor in the development of next-generation consumer gadgets and compact industrial devices.

Future Outlook for the PCB Industry and Key Players

The printed circuit board (PCB) industry is poised for significant growth in the coming years, driven by advancements in technology and increasing demand for electronic devices across various sectors. With the proliferation of smart devices, electric vehicles, and the Internet of Things (IoT), the need for high-quality PCBs is more critical than ever. Manufacturers are focusing on enhancing production capabilities, adopting automated processes, and integrating innovative materials that improve durability and efficiency. As the complexity of electronic products increases, the industry is also witnessing a shift toward miniaturized PCB designs that accommodate smaller, more powerful components.

Key players in the PCB market are investing in research and development to stay ahead of the curve. This includes exploring new fabrication techniques, increasing the use of eco-friendly materials, and developing advanced testing methods to ensure reliability and performance. Additionally, globalization is reshaping the competitive landscape, with businesses looking to expand their reach through strategic partnerships and collaborations. The future outlook suggests that as technology continues to evolve, the PCB industry will not only adapt but thrive, presenting new opportunities for innovation and growth for manufacturers willing to embrace change and sustainability.

Related Posts

-

Innovative Trends in PCB Printing That Will Transform the Electronics Industry

-

Top 5 Essential Features of High Quality PCB Boards for Your Projects

-

Top 5 US Based PCB Manufacturers to Watch in 2025

-

Top 10 Printed Circuit Board Manufacturers You Should Know

-

Transforming Industries: The Future of PCB Production and Its Impact on Technology

-

Top 10 Tips for Efficient Circuit Board Manufacturing Process Optimization